Measuring OLED Displays

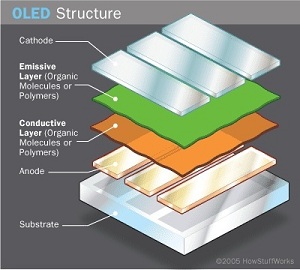

Organic Light-Emitting Diodes (OLEDs)

OLEDs are rapidly moving from the research lab to the fab. Their bright, ultra-thin, and dynamic characteristics make them appealing for many display applications, ranging from cell phones to TVs. The metrology of the many thin films that make up such displays is of critical importance, and too critical to be entrusted to traditional contact profilometry which can damage these relatively soft layers. Our F20-UV, F40-UV and F10-RT-UV instruments offer inexpensive, robust, and non-invasive metrology of simple prototype devices and fully-pixelated displays. Because our instruments are spectroscopic, one can also detect chemical changes that can occur in these atmospherically-sensitive materials.

Application Note RequestMeasure Transparent Conductive Oxides

Whether one encounters Indium Tin Oxide, Zinc Oxide, or Poly(3,4-ethylenedioxythiophene), our proprietary ITO optical model, coupled with our visible/near IR instruments, can solve for both thickness and optical constants at a fraction of the cost and effort of a spectroscopic ellipsometer.

Measure Complicated Organic Materials

A typical OLED requires a number of specialized layers: Hole Injection Layers, Hole Transport Layers, and Recombination/Emission layers. All these layers contain unusual organic molecules (either small molecule and/or polymers). Dealing with such materials could be a challenge for spectral reflectance due to their highly-anomalous optical dispersion but not for Filmetrics. Our materials database stretches back to the very beginnings of OLED and can deal with the high index dispersion and multiple UV features encountered with these molecules.

Films on Flexible Substrates

OLEDs offer the promise of enabling truly flexible displays. This requires measurement on highly birefringence substrates such as PET. This poses a serious problem for metrologies such as ellipsometry: one must either model this additional optical complication or sandpaper the PET’s backside. Neither of these approaches are required for our unpolarized spectral reflectance. This yields significant time savings for both user training and measurement cycle time.

Measurements Inside a Glove Box

OLED materials are extremely sensitive to water and oxygen. Many research groups require measurements inside the controlled atmosphere of a dry N2 glove box. The small form factor of our instruments and their modular, fiber-optic-based design easily allows real time “in-the-box” measurements of unencapsulated devices.

Filmetrics offers free trial measurements of OLED film samples, with results typically available in 1-2 days. Contact our thin-film experts to discuss your display material and OLED measurement application.

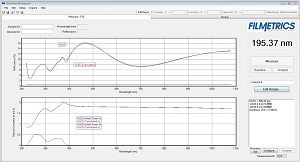

Thickness Measurement Example

In this example we show a thickness measurement of AlQ3 on glass. Filmetrics instruments can easily measure such organic materials including their complicated optical behavior in the UV region. Not only does this provide a non-destructive method (as compared to contact profilometry), but also allows the user to observe chemical changes in such OLED films. This high resolution result was obtained on a 17µm spot size F40-UV instrument. This spectrum corresponds to the area within the black square shown in the video image. Measuring multiple OLED films within a single pixel is now possible with such a setup.

Measurement Setup:

Contact Us Now

Contact Us Now

Search applications

-

Amorphous & Polysilicon

Measure thickness, crystallinity, and n and k of all forms of amorphous and polycrystalline silicon.

-

CMP

Our F80 Thickness Imaging products are used to measure oxide, STI, and metal CMP processes.

-

Dielectrics

Filmetrics stocks instruments that measure the thousands of dielectric films used throughout industry.

CVD, dielectrics, barrier, PECVD, passivation, insulator, protection, Al2O3, CoO, ZnO, MoO, TiO2, Cr2O3, Nb2O5

-

Hardcoat Thickness

Filmetrics systems are used widely in the automotive industry to verify hardcoat and primer thickness.

Acrylic, Automotive industry, Chemical resistance, Clear coating, Decorative coating, Hardcoat, Eyewear, Face shield, Hardcoat, Hardness, Interpenetration Layer, Marring, Ophthalmic lens, Optical quality, Plastic lens, Polycarbonate, Polyester, Siloxane, Primer, Protective film, Scratch resistant, Screen protection, Surface finish, Surface protection, Thermal cure, Top coating, Touch screen, UV coating, UV cure

-

IC Failure Analysis

The F3-sX is used throughout the chip making industry to measure backside thinning of silicon.

Failure Analysis, FA, Silicon, Si, Integrated circuit, IC, Polishing, Backside failure analysis, Silicon thinning

-

ITO & Other TCOs

Proprietary analysis algorithms allow one-click measurement of TCO thickness, index, and k.

Indium tin oxide, ITO, tin-doped indium oxide, Transparent conductive oxide, TCO, Display, Front contact, Transparent Electrode, LED, LCD, Solar, Fluorine-doped tin oxide, FTO, TEC, TEC glass, Aluminum zinc oxide, AZO, Aluminum-doped zinc oxide, Zinc oxide, iZO, Indium zinc oxide, IZO, zinc-doped indium oxide

-

Medical Devices

Measure thickness of angioplasty balloons, stent and implant coatings, and many others.

Stents, drug-coated stents, Drug-coating, Balloons, Angioplasty, Parylene, Microfluidic device, Air gap, Catheter, Membranes

-

Metal Thickness

Measure thickness, index, and k of metal films up to 50nm thick.

Metallized, Metallization, Foils, Stents, Mirrors, Steel, Stainless Steel, Gold, Nickel, Aluminium, Silver, Cobalt, Zinc, Molybdenum, Titanium, Chrome, Chromium, Niobium, Tungsten, Gallium, Germanium

-

OLEDs

Measure thickness and index of NPB, AlQ3, PEDOT, P3HT, soluble Teflons, etc…

PLED, AMOLED, Hole Transport (HT), Hole Injection Layer (HIL), Host Materials, anode, cathode, Alq3, NPB, phenylene vinylene, carbazole, thiophene, aniline, styrenesulfonate, phthalocyanine, naphthalene, fluorene, lithium, silver, ITO, calcium

-

Ophthalmic Coatings

Use the F10-AR to measure reflectance and color, as well as AR and hardcoat layer thicknesses.

eyeglasses, HC, hardcoat, scratch resistant, AR, anti-reflection, reflectance, UV curable, hydrophillic, polycarbonate, high index, CR39, MR-6, MR-7, Trivex

-

Parylene Coatings

Simply set your parylene-coated sample on the stage of the F3-CS to measure its thickness!

Conformal

-

Photoresist

We’ve measured dozens of different resists, and can generate index files for any resist you use.

SU-8, resist, Photoresist, PR, AZ, AZP, ZEP, positive, negative, g-line, i-line, KrF, PMMA, FEP, GRX, KMPR

-

Porous Silicon

Measure thickness, porosity, refractive index, and k of your porous silicon films.

-

Process Films

Filmetrics offers a full range of products for measuring semiconductor process films.

-

Refractive Index & k

Measure refractive index and extinction coefficient over wavelengths as wide as 190-1700nm.

n & k, complex, real , imaginary, refractive index, absorption, extinction coefficient, indices, Kramers-Kronig, optical dispersion, dielectric, Lorentz, Cauchy, photoresist, anomalous dispersion, path length

-

Silicon Wafers & Membranes

We offer tabletop, mapping, and production systems for measuring silicon up to 2mm thick.

-

Solar Applications

Measure CdTe, CdS, CIGS, amorphous-Si, TCOs, anti-reflection (AR) layers, and more...

Copper indium gallium diselenide, CIGS, Cadmium telluride, CdTe, Cad tel,, Amorphous silicon, Amorphous Si, a-Si, Cadmium sulfide, CdS, window layer, buffer layer, Thin-film photovoltaic, Thin-film PV, TFPV, photovoltaics, Solar, Solar cells, Inline, In-situ, Roll-to-roll, R2R, Evaporation, Sputtering, CVD, MOCVD, PECVD, Transparent conductive oxide, TCO, Indium tin oxide, ITO, tin-doped indium oxide

-

Semiconductor Teaching Labs

More than fifty Filmetrics F20s have been delivered for use in university teaching labs.

-

Web Coatings

Filmetrics systems are widely used in the polymer-films community to measure thickness in-line.

Roll to roll, Roll measurements, Roll systems, Rolling substrate, Roll fed, Roll web, Reel to reel , R2R, Web coater, Autoweb, In-line, In-line monitor, Online thickness, Line monitoring system, Precision measuring tools, Automatic, Feeding, Production, Multipoint, High speed